DIY Table Saw and Router Table

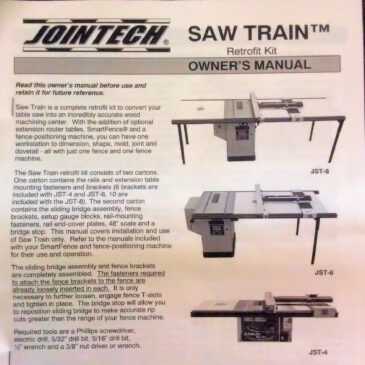

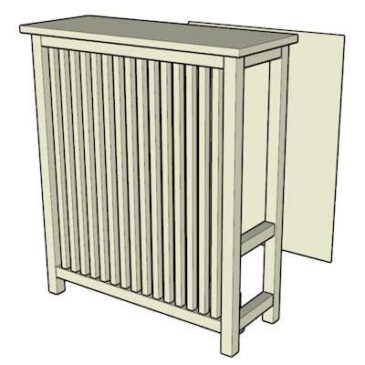

In this post I will walk thru a unique DIY project to build an inexpensive combo table saw, router table and maybe a jigsaw to add to my very limited space workshop. Dust collection will use a shopvac with a … Continued